PP Materials in Cable

Polypropylene (PP) is a widely used material in the cable industry due to its excellent properties and versatile applications. This thermoplastic polymer is known for its durability, insulation properties, and cost-effectiveness. In this article, we’ll explore PP’s role in cable manufacturing, its key properties, and its numerous applications.

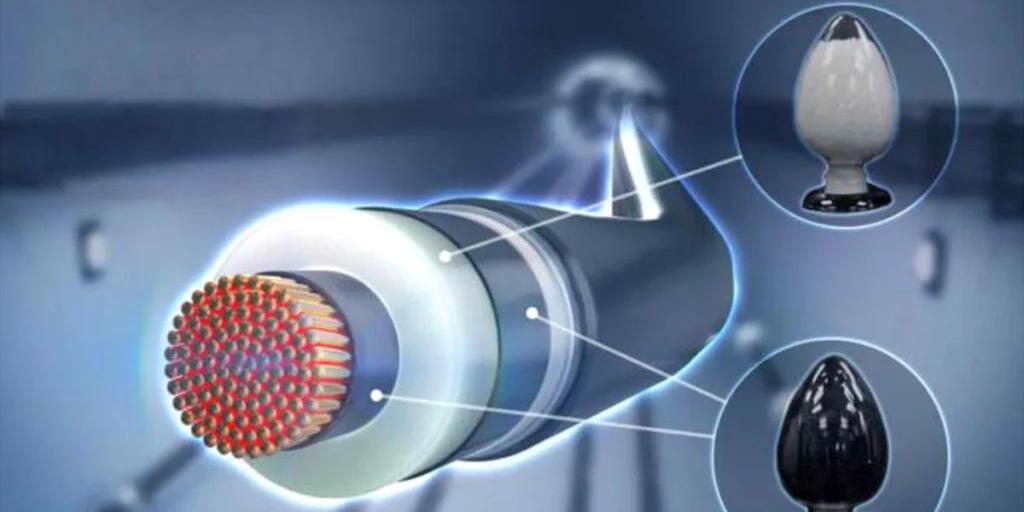

PP materials play a crucial role in cable insulation and sheathing. They are known for their excellent electrical properties, high resistance to wear, and ability to withstand harsh environmental conditions.

PP has become a standard material in cable construction due to its lightweight, flexible, and durable nature. Let’s dive deeper into the details of this material and its significance in cable applications.

What is PP (Polypropylene) and How is It Made?

Polypropylene (PP) is a thermoplastic polymer made from the polymerization of propylene monomers. It is one of the most versatile plastics used in cable manufacturing due to its excellent balance of properties, such as low density, high chemical resistance, and good electrical insulating capabilities. PP is produced through a polymerization process, where propylene is subjected to heat and pressure to form long polymer chains. These chains give PP its desirable characteristics, including high strength and flexibility.

The manufacturing process of PP involves two key steps: the polymerization of propylene into a resin and the extrusion of the resin into various forms such as pellets, films, and fibers. The versatility of PP allows it to be easily molded into desired shapes, which is why it is commonly used for insulation and sheathing in cables.

PP Manufacturing Process

| Process | Description | Benefit |

|---|---|---|

| Polymerization | The propylene is polymerized into PP resin | Forms the base material for various cable components |

| Extrusion | PP resin is melted and shaped into films and fibers | Easy to mold into required cable components |

Key Properties of PP in Cable Manufacturing

PP is highly favored in the cable industry because of its excellent electrical insulation properties. It has a high dielectric strength, which makes it an ideal material for insulating electrical cables. Additionally, PP is resistant to chemicals, oils, and solvents, which extends the lifespan of cables exposed to harsh environments.

Another significant property of PP is its excellent thermal stability, which allows it to function well in a wide range of temperatures, from very low to high. This makes PP ideal for cables used in outdoor environments or in high-temperature industrial applications.

Key Properties of PP

| Property | Description | Benefit |

|---|---|---|

| Electrical Insulation | Provides excellent dielectric strength | Ensures safe and efficient electrical performance |

| Chemical Resistance | Resistant to oils, solvents, and chemicals | Extends cable lifespan in harsh environments |

| Thermal Stability | Performs well in extreme temperatures | Ideal for use in both hot and cold environments |

Applications of PP Materials in Electrical and Communication Cables

PP is widely used in both electrical and communication cables. In electrical cables, PP is primarily used as an insulating material due to its excellent electrical properties. It prevents electrical leakage and ensures that cables can carry electrical currents safely. PP’s high dielectric strength makes it a reliable choice for various electrical installations.

In communication cables, PP is used for insulation and sheathing to protect the cable from external environmental factors like moisture, UV light, and physical wear. PP’s resistance to these factors ensures that communication cables maintain their integrity and performance over time, even in outdoor or harsh conditions.

Applications of PP in Cables

| Application | Description | Benefit |

|---|---|---|

| Electrical Insulation | Used for insulating electrical conductors | Ensures safe transmission of electricity |

| Communication Cables | Used for sheathing and protecting cables | Provides long-lasting protection in harsh conditions |

Advantages of Using PP in Cable Construction

The advantages of using PP in cable construction are numerous. One of the most notable benefits is its lightweight nature, which makes cables more flexible and easier to install. PP also has high abrasion resistance, which reduces the wear and tear on cables over time. Additionally, PP’s chemical resistance ensures that cables remain intact even when exposed to harsh substances like oils and solvents.

Moreover, PP is relatively easy to process and cost-effective, making it an attractive option for large-scale cable manufacturing. The material can be molded into various forms, such as films, sheets, and coatings, and is compatible with a range of manufacturing techniques, including extrusion and injection molding.

PP Advantages

| Advantage | Description | Benefit |

|---|---|---|

| Lightweight and Flexible | Easy to install and manage during cable production | Reduces installation costs and improves handling |

| Abrasion Resistance | Protects cables from wear and tear | Extends cable lifespan and reduces maintenance costs |

| Chemical and Cost Efficiency | Resistant to harsh substances and cost-effective | Provides reliable performance at a lower cost |

How PP Enhances Cable Performance and Durability

PP improves cable performance by enhancing its flexibility, electrical insulation, and durability. Due to its excellent insulating properties, PP helps prevent electrical leaks and ensures that cables function safely over long periods. It also helps maintain the integrity of the cables even under extreme conditions such as high temperatures or exposure to chemicals.

The durability of PP also means that cables remain operational for longer, reducing the need for replacements and minimizing maintenance costs. Additionally, the flexibility of PP enables cables to withstand bending and twisting without cracking or breaking, which is important in applications that require cables to be flexible and easy to install.

PP’s Impact on Cable Performance

| Feature | Description | Benefit |

|---|---|---|

| High Dielectric Strength | Prevents electrical leakage and ensures safe operation | Guarantees safe electrical performance |

| Flexibility and Durability | Allows cables to bend and withstand wear | Extends the service life of cables |

| Resistance to Harsh Conditions | Ensures cables maintain integrity under extreme conditions | Ideal for outdoor and industrial applications |

Considerations When Choosing PP for Cable Applications

When selecting PP for cable applications, it is essential to consider several factors. First, the operating environment of the cable must be taken into account. For example, cables exposed to high temperatures or harsh chemicals will require PP with enhanced chemical resistance or heat stability. Additionally, it is important to ensure that the PP material selected can be processed effectively using the cable manufacturing techniques, such as extrusion.

Furthermore, the electrical requirements of the cable should be evaluated. PP’s dielectric properties make it a suitable choice for many electrical and communication cables, but it is important to ensure that the material can meet the required performance standards.

Considerations When Choosing PP

| Consideration | Description | Benefit |

|---|---|---|

| Environmental Factors | Must withstand exposure to temperature extremes and chemicals | Ensures cable longevity and reliability in harsh environments |

| Electrical Properties | Should provide sufficient electrical insulation | Guarantees safe and efficient cable performance |

Conclusion

Polypropylene (PP) is a versatile and durable material that plays a crucial role in cable manufacturing. Its excellent electrical properties, chemical resistance, and flexibility make it a top choice for a wide range of cable applications.